Honor

Because of its simple and flexible operation control, the electric fork lift trucks is much lighter than the internal combustion pallet forklift. Its electric steering system, acceleration control system, hydraulic control system and brake system are all controlled by electrical signals, greatly reducing The labor intensity of the operator is very helpful for improving the efficiency of work and the accuracy of the work. Compared with internal combustion fork lift trucks, the advantages of low noise and no exhaust emissions of electric vehicles have also been recognized by many users. In addition, there are some technical reasons for choosing an electric pallet fork lift trucks. The rapid development of electronic control technology has made the operation of electric pallet forklift more and more comfortable, the wider the scope of application, and the more and more solutions for logistics. In these respects, the market demand for electricfork lift trucks will certainly grow faster and faster, and the market share of electric pallet forklift will become larger and larger.

The electric fork lift trucks adopts electric drive, which has the advantages of no pollution, easy operation, energy saving and high efficiency compared with the internal combustion pallet forklift. With the development of the economy and the improvement of environmental protection and energy conservation requirements, electric fork lift trucks have developed rapidly. Market sales have increased year by year. Especially in the port, warehousing and tobacco, food, textile and other industries, electric pallet forklift are gradually replacing internal combustion fork lift trucks.

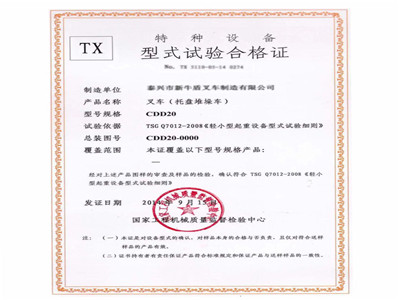

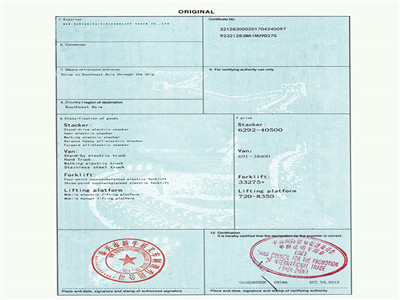

After the pallet forklift was included in the management of the national special equipment, the method of the type test and the traditional product inspection have undergone great changes. In order to be in line with international standards and to strengthen the management of fork lift trucksproduction, safety inspection projects account for a large proportion of type tests. In order to provide high-quality electric pallet forklift and other logistics handling equipment, NEW NEW TON Co., Ltd. is not only highly rigorous in the production process, but also carries out safety and quality inspections for fork lift trucks and other equipment to ensure the safety of customers.

Pallet forklift daily operation procedures and precautions:

1. Fork lift trucks maintain proper starting speed at startup, not too aggressive.

2. Observe the voltage of the voltmeter. If it is lower than the limit voltage, the pallet forklift should stop running immediately.

3. During the walking process, the fork lift trucks does not allow the direction switch to be changed to change the direction of travel to prevent burning of electrical components and damage to the gears.

4. Fork lift trucks driving and lifting should not be carried out at the same time.

5. Fork lift trucks pay attention to the drive system. The sound of the steering system is normal. If abnormal sounds are found, it is necessary to eliminate the faults in time.

6. Pallet forklift decelerate in advance when changing.

7. When pallet forklift working in poor road conditions, it is important to reduce it properly and should reduce the speed of travel.